- Record: found

- Abstract: found

- Article: found

A life cycle assessment of reprocessing face masks during the Covid-19 pandemic

Read this article at

Abstract

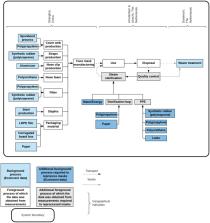

The Covid-19 pandemic led to threatening shortages in healthcare of medical products such as face masks. Due to this major impact on our healthcare society an initiative was conducted between March and July 2020 for reprocessing of face masks from 19 different hospitals. This exceptional opportunity was used to study the costs impact and the carbon footprint of reprocessed face masks relative to new disposable face masks. The aim of this study is to conduct a Life Cycle Assessment (LCA) to assess and compare the climate change impact of disposed versus reprocessed face masks. In total 18.166 high quality medical FFP2 face masks were reprocessed through steam sterilization between March and July 2020. Greenhouse gas emissions during production, transport, sterilization and end-of-life processes were assessed. The background life cycle inventory data were retrieved from the ecoinvent database. The life cycle impact assessment method ReCiPe was used to translate emissions into climate change impact. The cost analysis is based on actual sterilization as well as associated costs compared to the prices of new disposable face masks. A Monte Carlo sampling was used to propagate the uncertainty of different inputs to the LCA results. The carbon footprint appears to be 58% lower for face masks which were reused for five times compared to new face masks which were used for one time only. The sensitivity analysis indicated that the loading capacity of the autoclave and rejection rate of face masks has a large influence on the carbon footprint. The estimated cost price of a reprocessed mask was €1.40 against €1.55. The Life Cycle Assessment demonstrates that reprocessed FFP2 face masks from a circular economy perspective have a lower climate change impact on the carbon footprint than new face masks. For policymakers it is important to realize that the carbon footprint of medical products such as face masks may be reduced by means of circular economy strategies. This study demonstrated a lower climate change impact and lower costs when reprocessing and reusing disposable face masks for five times. Therefore, this study may serve as an inspiration for investigating reprocessing of other medical products that may become scarce. Finally, this study advocates that circular design engineering principles should be taken into account when designing medical devices. This will lead to more sustainable products that have a lower carbon footprint and may be manufactured at lower costs.

Related collections

Most cited references18

- Record: found

- Abstract: found

- Article: not found

Critical Supply Shortages — The Need for Ventilators and Personal Protective Equipment during the Covid-19 Pandemic

- Record: found

- Abstract: not found

- Article: not found

The ecoinvent Database: Overview and Methodological Framework (7 pp)

- Record: found

- Abstract: found

- Article: not found