- Record: found

- Abstract: found

- Article: found

Mechanical Performances of Lightweight Sandwich Structures Produced by Material Extrusion-Based Additive Manufacturing

Read this article at

Abstract

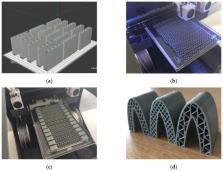

Material Extrusion-Based Additive Manufacturing Process (ME-AMP) via Fused Filament Fabrication (FFF) offers a higher geometric flexibility than conventional technologies to fabricate thermoplastic lightweight sandwich structures. This study used polylactic acid/polyhydroxyalkanoate (PLA/PHA) biodegradable material and a 3D printer to manufacture lightweight sandwich structures with honeycomb, diamond-celled and corrugated core shapes as a single part. In this paper, compression, three-point bending and tensile tests were performed to evaluate the performance of lightweight sandwich structures with different core topologies. In addition, the main failure modes of the sandwich structures subjected to mechanical tests were evaluated. The main failure modes that were observed from mechanical tests of the sandwich structure were the following: face yielding, face wrinkling, core/skin debonding. Elasto-plastic finite element analysis allowed predicting the global behavior of the structure and stressing distribution in the elements of lightweight sandwich structures. The comparison between the results of bending experiments and finite element analyses indicated acceptable similarity in terms of failure behavior and force reactions. Finally, the three honeycomb, diamond-celled and corrugated core typologies were used in the leading edge of the wing and were impact tested and the results created favorable premises for using such structures on aircraft models and helicopter blade structures.

Related collections

Most cited references30

- Record: found

- Abstract: not found

- Article: not found

3D printed polyurethane honeycombs for repeated tailored energy absorption

- Record: found

- Abstract: not found

- Article: not found

3D printed architected polymeric sandwich panels: Energy absorption and structural performance

- Record: found

- Abstract: not found

- Article: not found